Inner Arm For ESP Rapping System

230 INR/Piece

Product Details:

- Product Type Inner Arm For ESP Rapping System

- General Use ESP

- Material Other

- Feature High Performance High Efficiency Simple Control

- Color Blue

- Warranty 1 Years

- Click to view more

X

Inner Arm For ESP Rapping System Price And Quantity

- 230 INR/Piece

- 100 Piece

Inner Arm For ESP Rapping System Product Specifications

- High Performance High Efficiency Simple Control

- Other

- Inner Arm For ESP Rapping System

- ESP

- 1 Years

- Blue

Inner Arm For ESP Rapping System Trade Information

- Cash Advance (CA) Cash in Advance (CID)

- 10000 Piece Per Month

- 7 Days

- All India

Product Description

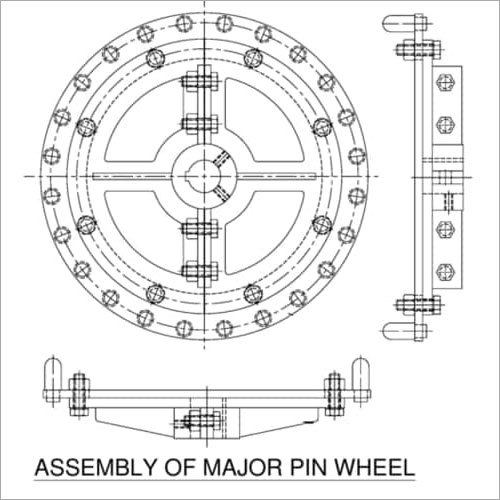

The Inner Arm for ESP Rapping System is a critical component used in electrostatic precipitators (ESPs) for removing particulate matter from industrial gas streams. This specially designed arm is responsible for delivering precise and efficient rapping or vibrating action to dislodge collected dust from the electrodes, ensuring continuous and optimal performance of the ESP.

FAQs :

Q: What is the Inner Arm for ESP Rapping System?

A: The Inner Arm for ESP Rapping System is a mechanical device used in electrostatic precipitators to facilitate the cleaning or rapping process. It is specifically designed to deliver controlled vibrations or impacts to the ESP electrodes, dislodging accumulated dust and allowing it to fall into hoppers or collecting devices for disposal.

Q: How does the Inner Arm in ESP Rapping System work?

A: The Inner Arm is strategically positioned inside the ESP to ensure proper contact with the electrodes. It is connected to a rapping mechanism, typically an electric motor, which imparts rapid and precise movements to the arm. These movements generate mechanical vibrations or impacts that dislodge the collected dust, allowing it to be collected and removed from the ESP.

Q: What are the key features of the Inner Arm for ESP Rapping System?

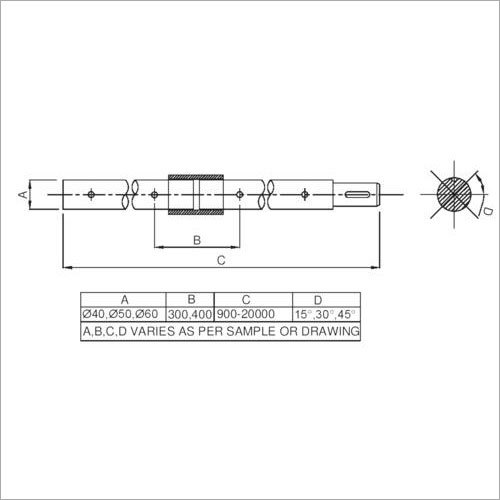

A: The Inner Arm for ESP Rapping System is designed to withstand the harsh operating conditions within an electrostatic precipitator. It is constructed from durable materials, such as high-strength steel or alloy, to ensure reliability and longevity. The arm is engineered to deliver consistent rapping forces while minimizing wear on the electrodes and other system components.

Q: Why is the Inner Arm important in ESP Rapping System?

A: The Inner Arm plays a crucial role in maintaining the performance and efficiency of an electrostatic precipitator. Its precise rapping action ensures effective removal of accumulated dust from the electrodes, preventing excessive buildup that can hinder the ESP's ability to capture particulate matter. Regular and proper rapping helps optimize the ESP's performance, reducing emissions and maintaining compliance with environmental regulations.

Enter Buying Requirement Details